Design and Manufacturing

The Eveque Standard

At the heart of Eveque is our design and manufacturing capabilities. For over 44 years, we’ve provided UK clients with high-quality products and solutions backed by excellent service. We’re passionate about collaborating and producing bespoke high-quality products that empowers everyone that we work with to succeed.

Gym Mats Sold

Bespoke Protective Padding Units / Matting Designed and Manufactured.

MTE Units Sold

Bespoke Hot Tub Covers Designed and Manufactured

Our Design & Manufacturing Capabilities

Bringing Ideas to Life

Our in-house technological capabilities will bring your custom designs to life. Our expert team skilfully utilises a range of advanced technologies including:

CAD & SketchUp Design Software

Zünd CNC

Croma’s 5-axis CNC

UV Printers

Hyma Ban Saw

Triad, Heat and High Frequency Welders

High Quality Adhesives and bonding techniques

Durkopp Adler Sewing Machines

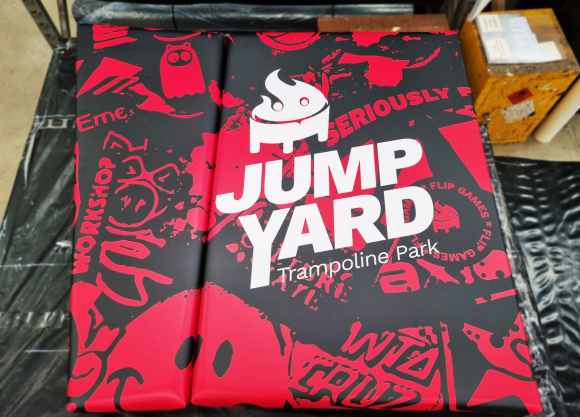

Our Projects

FAQs

We source our materials from reputable UK suppliers and all manufacturing materials undergo rigorous testing to ensure they meet our high-quality standards.

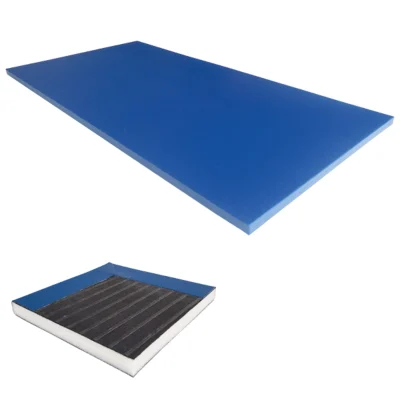

Our top-of-the-range machinery allows us to work with an extensive selection of materials in our design and manufacturing processes, including PVC, PU foam (Polyurethane foam), PE Foam (Polyethylene foam), EPS (expanded polystyrene), plastic correx, plywood and many more. We welcome new product inquiries, so please contact us to explore how our versatile capabilities can meet your needs.

Quality underpins every decision and action we take. At each stage of the manufacturing process, the products are inspected, with a final check taking place in despatch to ensure they are manufactured to the highest quality before leaving our premises.

We have a talented in-house team of Product Designers, who will be on hand as part of the design process to bring your product conception to life. Using the latest design software including CAD, SketchUp and Adobe suite we can offer a range of design services from renders, 3D modelling, prototyping and concept idealisation.

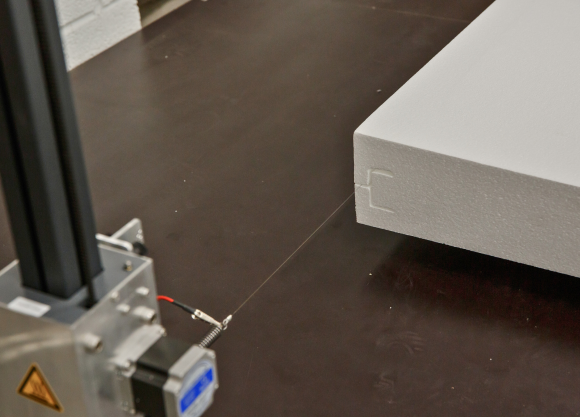

Within our premises, we host an array of state-of-the-art machinery ensuring the highest quality material processing and providing us with exceptional flexibility to be able to handle diverse project requirements. Our advanced technologies include:

- Zünd CNC

- Croma’s 5-axis CNC

- UV Printers

- Hyma Ban Saw

- Triad Welder

- Heat Welder

- High Frequency Welder

- High Quality Adhesives and bonding techniques

- Durkopp Adler Sewing Machines

When sending designs/artwork to our team, please send all files as an AI or EPS file. If you have any questions, please contact our team through the contact us form here.